“`Partially threaded screws are designed to prevent loosening and offer added security. These screws will stop automatically once they reach the end of the threading, ensuring a tight fit. They can be used with or without nuts and washers, just like fully threaded screws.“`

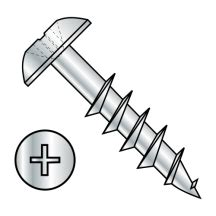

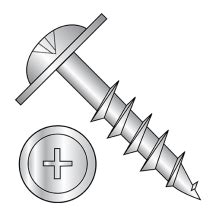

Why do wood screws not have threads all the way?

A wood screw with an unthreaded shank at the top has a unique advantage over regular screws. While the tip of the screw pulls it into the wood, the shoulder portion of the screw slides through the first layer of wood and pulls it against the head. This design ensures a secure and tight fit, making it ideal for woodworking projects where stability is crucial.

Are partially threaded screws better?

Partial threads offer several advantages over full threads, including increased strength, shear resistance, and improved alignment. They are particularly useful in applications where grip is less important than these other factors, such as motor mounts, water pumps, and alternators. In fact, many manufacturers specifically recommend the use of partial threads in these types of applications. So if you’re looking for a reliable and durable fastening solution, consider using partial threads for your next project.

When should I use fully threaded wood screws?

A screw that is fully threaded is designed with grooves that run from the head of the screw all the way to the tip. This type of screw is ideal for applications that require a strong grip, as the full thread allows for even pressure distribution along the entire length of the shaft. The head of the screw provides the greatest holding strength, making it a reliable choice for heavy-duty tasks.

What is the difference between fully and partially threaded screws?

Triple-delimited paragraph:

“`When it comes to bolts, there are two main types: fully threaded and partially threaded. Fully threaded bolts have threads that run the entire length of the bolt, while partially threaded bolts have an unthreaded area just beneath the head, known as the grip length, and then have partial threading for the rest of the bolt length. The grip length provides a non-threaded area for the bolt to grip onto, which can be useful in certain applications. However, fully threaded bolts provide more consistent and even clamping force, making them a better choice for many applications.

“`

What are fine threaded screws best for?

When it comes to applications that involve high levels of vibration, fine thread fasteners are the way to go. These types of fasteners are commonly used in machine parts, transmission parts, and hydraulic systems due to their ability to withstand vibration. The best materials for fine thread screws include hardwood, which provides a strong and durable hold. So, if you’re looking for a reliable fastener that can handle vibration, consider using fine thread screws made from hardwood.

What is partially threaded?

It’s likely that you’re familiar with screws, but have you heard of partially threaded screws? These fasteners are unique in that they only have partial external threading on the shaft. Despite this, they still have a pointed tip that’s used to drive them into an object or surface. The lack of complete external threading on the shaft sets them apart from other screws.

Why do screws have different threads?

It’s crucial to choose the appropriate screw thread for your specific needs. Not all screw threads are created equal, and each one is designed to suit different tasks and material sizes. Some require pre-drilled holes, while others have sharp designs that allow for drilling directly into softer materials like wood. It’s important to consider these factors when selecting a screw thread to ensure that it will work effectively and efficiently for your intended application.

What are the two types of threading?

Triple-delimited paragraph:

“`When it comes to threads, there are two main types: straight threads and tapered threads. Straight threads have a consistent diameter throughout the part, with a parallel profile. On the other hand, tapered threads gradually decrease in diameter as the part progresses, following the thread profile. Both types of threads have their own unique advantages and disadvantages, and the choice between them depends on the specific application and requirements.

“`

What do you call a threaded screw with no head?

Triple-delimited paragraph:

“`When it comes to set screws, they are typically headless, which means that they are fully threaded and lack a head. In the UK, these are known as grub screws. To drive a blind set screw, an internal wrenching drive, such as a hex Allen key, is almost always used.“`

Why do electricians use square head screws?

Rewritten paragraph: “`If you’re looking for a more efficient way to drive screws, consider using square drive screws. These screws have a smaller body diameter, which means less resistance when driving them in. Additionally, the sharp point allows you to start the screw without needing a pilot hole, saving you time and effort.“`

What are the 4 types of screw threads?

When it comes to clamps and vises, there are several types of threads to consider. These include Standard threads, ACME threads, Buttress threads, and Square threads. Each of these threads has its own unique benefits and can be used for different purposes. It’s important to choose the right thread for your specific needs to ensure optimal performance and functionality.

What is the purpose of a headless screw?

Headless Compression Screws are a versatile medical device that can be used in a variety of bone reconstruction procedures. These screws are particularly useful in osteotomy, arthrodesis, joint fusion, fracture repair, and fixation of bones that are appropriate for the size of the device. They are specifically designed for bone fixation in the hand and foot following trauma or osteotomy. With their unique design, Headless Compression Screws provide excellent compression and stability, which can help to promote faster healing and reduce the risk of complications.

Whether you are a patient or a healthcare professional, Headless Compression Screws are an excellent choice for bone fixation in a variety of situations.

What are the 3 types of screw heads?

There are various types of screw drives available, each with its own unique features and benefits. Some of the most common screw drive types include slotted, Phillips, and Phillips tamper-resistant. Slotted screw drives are the oldest and simplest type, featuring a single slot that requires a flathead screwdriver. Phillips screw drives, on the other hand, have a cross-shaped slot that requires a Phillips screwdriver.

This type of screw drive is designed to prevent the screwdriver from slipping out of the slot, making it easier to apply torque. Finally, Phillips tamper-resistant screw drives are similar to Phillips screw drives, but they have a small pin in the center of the slot that prevents unauthorized removal. Overall, understanding the different types of screw drives can help you choose the right one for your specific needs and applications.

Why do Phillips head screws exist?

The Phillips-head screw and screwdriver were specifically created for use with power tools, particularly those found on assembly lines. The screw’s shallow, cruciform slot is designed to allow the screwdriver’s tapering cruciform shape to automatically seat itself when contact and rotation are established. This design makes it easier and faster to use power tools for assembly line work.

Why are flat head screws good?

FLAT HEAD SLOTTED screws are perfect for applications that require a strong fastener with a flush mount. Their low-profile and countersunk head make them ideal for projects that involve moving parts passing over a fastened area. These screws are commonly used in various industries, including automotive, construction, and electronics. They are also popular in woodworking and furniture making.

The slotted design of these screws allows for easy installation and removal using a flathead screwdriver. Overall, FLAT HEAD SLOTTED screws are a reliable and versatile option for any project that requires a secure and flush fastener.

How do you use partially threaded screws?

Partially threaded screws are commonly used in orthopedic surgeries to fix fractures and bone injuries. The threaded portion of the screw is inserted into the bone, providing stability and support. The unthreaded portion of the screw is left exposed, allowing for easy removal if necessary. To use a partially threaded screw, the surgeon will first drill a hole into the bone, then insert the screw using a screwdriver or drill.

The threaded portion of the screw should be inserted into the bone, while the unthreaded portion should be left exposed. It is important to use the correct size and type of screw for the specific injury being treated, as well as to follow proper surgical techniques to ensure the best possible outcome for the patient.

Are all machine screws fully threaded?

“`When it comes to machine screws, the threaded shank is a crucial component. This shank is the main shaft of the screw that is driven into a tapped hole. However, it’s important to note that not all machine screws have the same amount of threading. Some may have a partially threaded shank, while others have a fully threaded shank.

Understanding the threading of a machine screw is important for selecting the right screw for your project.“`

What does full thread mean?

A bolt with a full thread has no section without threads, which means that the threads extend from the head to the end of the bolt. If you don’t need as much alignment or shear strength, then a full thread bolt is the way to go. This type of bolt offers exceptional grip strength, making it a great choice for certain applications.

What is the difference in screw threads?

When it comes to threads, there are two main types: coarse and fine. Coarse threads have a larger pitch, meaning there are fewer threads per axial distance. On the other hand, fine threads have a smaller pitch, resulting in more threads per axial distance. The threadform of coarse threads is larger relative to the screw diameter, while the threadform of fine threads is smaller relative to the screw diameter.

Related Article

- Why Are Womens Shorts So Short?

- Why Are Wire Cutters Called Dykes?

- Why Are Wine Bottles 750 Ml?

- Why Are Window Treatments So Expensive?

- Why Are Window Shades So Expensive?

- Why Are Window Blinds So Expensive?

- Why Are Wiener Dogs So Long?

- Why Are White German Shepherds Disqualified?

- Why Are White Fillings So Expensive?

- Why Are Westwind Jets So Cheap?